Blog

Roughly 200 people per year die because of Legionella and these deaths are entirely avoidable.

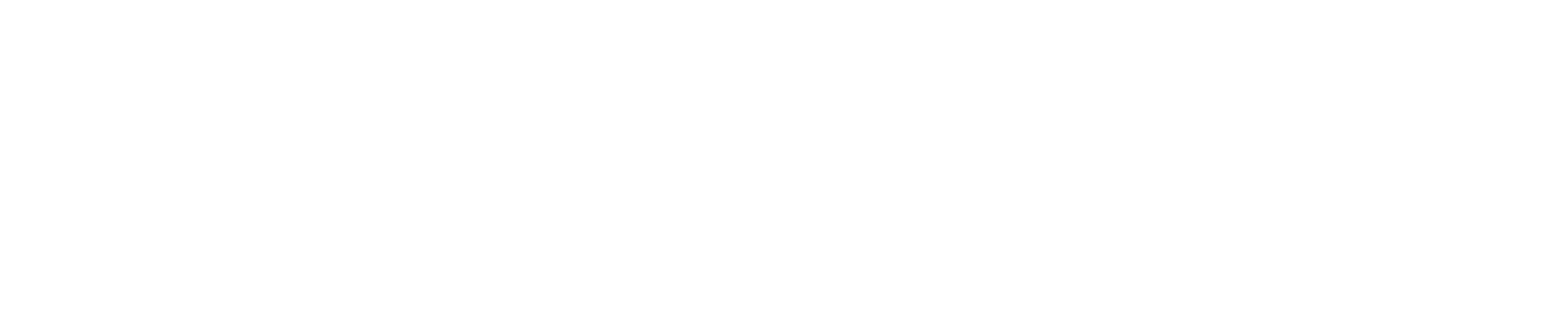

The design of most pipework and hot water systems aims to avoid temperatures within the system that encourage the growth of Legionella. Legionella is a bacterium that is naturally found in small quantities in most water systems, but faulty systems and poor system management will increase the growth of Legionella which can cause potentially fatal consequences.

Roughly 200 people per year die because of Legionella and these deaths are entirely avoidable. Maintaining a supply temperature of at least 60°C from the heat source and/or storage vessel (calorifier) is essential in avoiding the build-up and growth of Legionella as it would not survive these temperatures.

Hotels, care homes and large private residential properties need to ensure they are protecting themselves against Legionella.

The hot water priority circulating loop should be designed to give a return temperature very similar to the outlet temperature, if the pipe work is well insulated. Ensuring you have appropriate means for measuring temperature by manually checking with a thermometer or with a built-in BMS system, is essential.

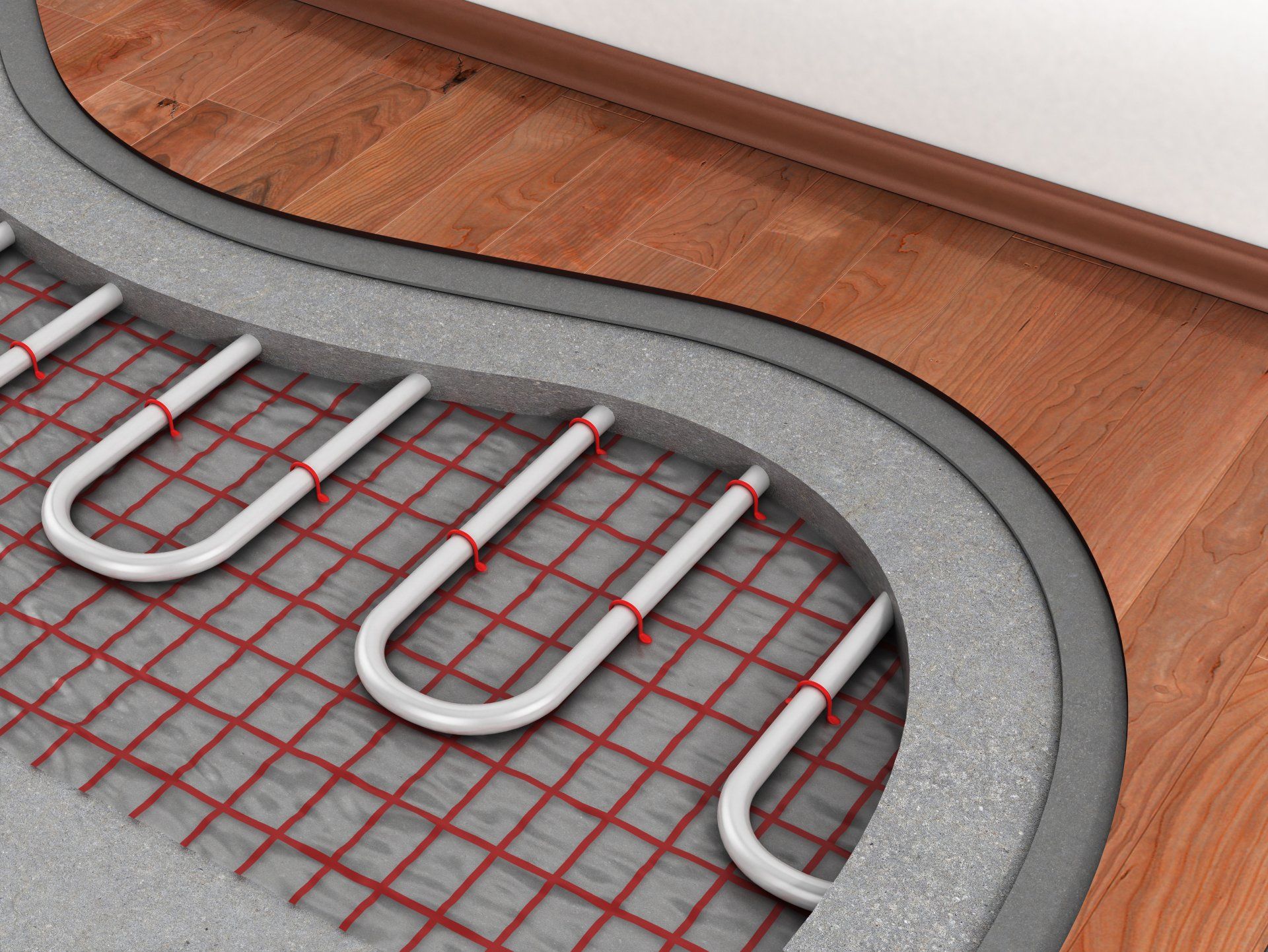

All pipe branches (subordinate loops) to outlets such as showers, basins or baths, should be sufficiently insulated to enable the hot water at each outlet to reach 50°C or above within one minute of turning on the tap.

This is written in the HSE regulations (L8) about water temperature testing and is the basic rule of thumb for a standard hot water system. However, many large buildings, including hotels, care homes and large private residential properties need to look a little closer at the HSE guidance to ensure they are protecting themselves against Legionella.

Are you testing your system at least quarterly?

If a tap took 55 seconds to produce hot water of 50°C or more it would “pass the test” as it would be under the one-minute guideline. However, the same tap could only be a few metres away from the subordinate loop and should therefore only take a few seconds to heat up. This kind of reading would tend to indicate a significant issue with the pump and/or balancing valves on the subordinate loops. These issues would contribute to the growth of Legionella and presumptive CFUs (other potentially harmful bacteria or algae) in the subordinate loop and yet, the whole system could be said to have “passed the test”. Knowing the layout and schematics of your hot water system is essential as by law, commercial businesses and properties need to test the subordinate loops at least quarterly, and monthly if there have been previous issues with Legionella.

If you know the length and diameter of pipe from the subordinate loop, it is fairly straightforward to calculate the time it takes to get over 50°C. If, after your calculations, hot water is slow to arrive at your tap, it will mean that the subordinate loop is not moving adequately and can grow Legionella.

New title

It’s well worth getting a plumbing specialist to balance your hot water system flow and return circuits in order to avoid long lengths of stagnant pipework. If there is no flow or poor flow in your pipework, slow moving water is likely to be at a lower temperature, encouraging bacterial growth.

Dead legs and redundant pipework wherever possible, should always be removed and spare bedrooms with en-suites that are rarely used should, be flushed at least weekly to prevent stagnation. It’s often surprising how many people have sinks or basins that remain unused in their homes without realising that they are potential breeding grounds for Legionella.

If you need support to inspect or balance your hot water system and identify any Legionella risks, please contact Adam by calling on 01983 608308 or click here to send a message.

Share this story

More articles